Your soap bars will cure fastest at temperatures between 70-75°F (21-24°C), which provides ideal conditions for chemical reactions without risking defects. If you're using hot process soap, you can speed up curing at 131-160°F. However, don't exceed 80°F (27°C) with cold process soaps, as this can cause soda ash formation. You'll also need to maintain humidity below 40% and guarantee proper air circulation to achieve the quickest curing results. Understanding these environmental factors can transform your soap-making success.

The Science Behind Temperature and Soap Curing

When it comes to soap curing, temperature plays a pivotal role in determining how quickly your bars will reach their ideal state. You'll find that maintaining temperatures between 70-75°F (21-24°C) provides the sweet spot for optimal chemical reactions during the curing process.

Understanding the science, you'll notice that temperature variations can dramatically affect your soap's development. For every 10°C (18°F) increase, your reaction rate doubles, speeding up the hardening process.

However, you'll want to avoid temperatures above 80°F (27°C), as they can cause unwanted effects like soda ash formation. Similarly, if your curing area drops below 65°F (18°C), you'll experience significant slowdowns in the process.

To achieve the best results, guarantee proper air circulation while maintaining consistent temperature levels, as this combination promotes effective moisture evaporation and superior soap quality.

Optimal Temperature Ranges for Different Soap Types

You'll find that cold process soaps cure best between 70-75°F, allowing for proper saponification without compromising the final product's quality.

If you're making hot process soap, higher temperatures of 131-160°F can speed up curing, though you'll need to watch for potential defects at these elevated ranges.

For melt-and-pour soaps, maintaining temperatures between 120-125°F during the pouring phase helps achieve the best results while preventing cloudiness or sweating in your finished bars.

Cold Process Soap Range

Three key temperature ranges define successful cold process soap making, each serving distinct purposes.

You'll find the ideal range between 120-130°F for both oils and lye, which guarantees proper saponification and prevents false trace issues.

If you're working with heat-sensitive ingredients like milk or certain fragrance oils, cool temperatures of 100-110°F will serve you better.

For vibrant colors and reduced soda ash, consider hot soaping at 131-160°F, particularly when using beeswax or LabColors.

Remember to keep your lye and oil temperatures within 10 degrees of each other for smooth mixing.

When crafting soaps with high olive oil content, you'll need to plan for a longer cure time of 3 to 8 weeks, especially in humid conditions, regardless of your chosen temperature range.

Hot Process Ideal Heat

To achieve the fastest curing times in hot process soaping, maintaining temperatures between 131-160°F proves essential for superior results. You'll find that this high heat range promotes prime gel phase and enhances your soap's color vibrancy. When you're working with beeswax or heat-sensitive additives like LabColors, these elevated temperatures guarantee proper integration and help prevent common defects.

| Process Stage | Temperature (°F) | Benefits |

|---|---|---|

| Initial Melt | 131-140 | Prevents soda ash |

| Gel Phase | 141-150 | Accelerates saponification |

| Peak Heat | 151-160 | Enhances color vibrancy |

| Cool Down | 130-140 | Promotes firm texture |

To fully cure your bars effectively, keep your soap mixture well-insulated during the process. This consistency in temperature helps achieve uniform saponification and produces firmer bars more quickly than lower temperature methods.

Melt-Pour Temperature Guidelines

While hot process soaping requires higher temperatures, melt-and-pour techniques demand precise temperature control for best results.

You'll want to maintain your base at 130°F during melting to prevent glycerin rivers and guarantee clarity. Don't exceed 160°F, as this can damage your soap's quality and cause unwanted discoloration.

For the perfect pour, let your mixture cool to 120-140°F. This temperature range helps you avoid bubbles and defects while achieving a smooth, consistent texture.

When it comes to curing, place your bars in a cool, dry environment around 70-75°F to promote proper water loss. High humidity can interfere with the hardening process, so choose a well-ventilated space for best results.

Following these temperature guidelines will help you create professional-quality melt-and-pour soap bars every time.

Humidity's Role in Temperature Control

Although temperature plays a significant role in soap curing, humidity levels can make or break your curing timeline.

You'll want to keep your humidity below 40% for best results, as higher levels can dramatically slow down the curing process. In fact, when relative humidity exceeds 60%, you might find your soap taking up to ten times longer to cure properly.

To maintain ideal curing conditions, follow these key practices:

- Monitor both temperature and humidity levels consistently, as they work together to affect your cure time.

- Use fans to blow air across your curing soaps, helping reduce vapor pressure and speed up moisture evaporation.

- Keep your curing area's humidity below 40%, as even a tiny 0.1% increase in moisture can extend your cure time by 30%.

Air Circulation and Heat Distribution

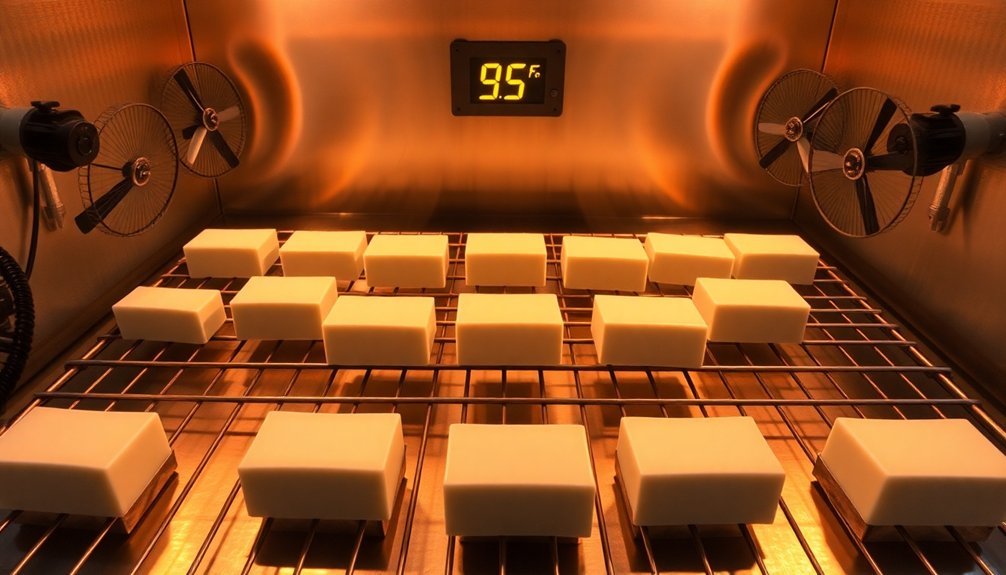

Strategic fan placement and shelf spacing work together to create the ideal curing environment for your soap bars.

You'll want to position fans at angles that promote consistent airflow across all shelves while avoiding direct blasts that could cause uneven drying.

Keep your wire racks spaced at least 2-3 inches apart to guarantee heat distributes evenly and air circulates freely around each bar.

Strategic Fan Placement

Proper fan placement plays an essential role in accelerating the soap curing process by enhancing air circulation throughout your workspace.

You'll want to position your fans strategically to create cross-ventilation while maintaining temperatures between 70-75°F and keeping humidity below 40%.

Here's how to maximize your fan setup:

- Position fans to create indirect airflow around your soap bars – direct contact can cause uneven drying and surface cracking.

- Set up multiple fans to establish cross-ventilation patterns, ensuring consistent air movement throughout your curing area.

- Monitor and adjust fan positions regularly to adapt to environmental changes and maintain ideal drying conditions.

Remember to place your fans in a well-ventilated space, as this combination will help remove excess moisture efficiently while promoting even temperature distribution throughout your curing process.

Optimal Shelf Spacing

Effective shelf spacing serves as the backbone of successful soap curing, working hand-in-hand with your ventilation system. By placing your bars on wire racks with 1-2 inches of separation between them, you'll create ideal conditions for airflow around each piece.

You'll want to maximize air circulation by utilizing multiple shelves in your curing area. This setup increases the surface area exposed to moving air, which speeds up the drying process.

Don't forget to place your bars on wire racks rather than solid surfaces – this allows air to reach all sides of your soap, preventing moisture buildup and soda ash formation.

Remember to rotate your bars regularly during the curing phase. This simple practice guarantees even exposure to air and heat, resulting in consistently hardened, high-quality soap bars.

Common Temperature-Related Curing Issues

While soap making can be a rewarding craft, temperature-related issues often pose important challenges during the curing process.

You'll find that maintaining the perfect balance between temperature and humidity is essential for achieving properly cured soap bars.

Here are the most common temperature-related issues you'll encounter:

- When your curing area drops below 65°F, you'll notice noticeably slower hardening times, forcing you to wait longer for finished bars.

- High humidity levels above 60% can make your curing time increase by up to ten times the normal duration.

- If temperatures rise above 80°F, your soap may cure faster but risk developing unsightly soda ash and glycerin rivers.

To avoid these issues, keep your curing area at 70-75°F with humidity below 40%, and always monitor the dew point to prevent condensation formation.

Storage Solutions for Temperature Management

Managing temperature-related issues starts with smart storage solutions for your soap bars.

You'll want to maintain a consistent temperature between 70-75°F (21-24°C) in your storage area to optimize curing speed and quality. Wire racks are your best friend here – they'll promote essential air circulation around your bars.

If you're dealing with humidity challenges, don't hesitate to use a dehumidifier to keep levels below 40%. This step is vital since excess moisture can greatly slow down the curing process.

Place your storage setup away from windows and heat sources to avoid temperature fluctuations that could lead to soda ash formation.

Seasonal Temperature Adjustments

As temperatures fluctuate throughout the year, you'll need to adapt your soap curing strategy to maintain ideal results. During warmer seasons, you can accelerate curing by maintaining temperatures between 70-75°F (21-24°C).

However, high humidity levels above 60% can greatly slow down your curing process, so it's essential to monitor both temperature and humidity for best results.

Monitor both temperature and humidity closely – excess moisture in the air can significantly delay proper soap curing.

Here's how you can enhance your seasonal curing process:

- Use fans or create a well-ventilated space to improve air circulation and speed up moisture evaporation.

- Reduce water content in your recipes during hot months to achieve firmer bars more quickly.

- Monitor ambient temperature, as every 10°C (18°F) increase can double your curing reaction rate.

Remember that cooler temperatures below 65°F (18°C) will extend your curing time, so plan accordingly during colder seasons.

Testing Methods for Cure Progress

Monitoring your soap's curing progress requires specific testing methods to assure quality results. You'll need a pH meter to accurately track the saponification process and confirm your soap reaches the proper alkalinity level.

To assess cure progress, you can perform several tests. Press your finger against the bar to check its firmness – a harder texture indicates successful curing.

Try the water test by submerging a small soap sample; properly cured bars will resist moisture absorption. Watch for visual indicators like soda ash or glycerin rivers, which might signal unsuitable curing conditions.

Additionally, weigh your bars regularly; consistent weight loss means moisture is evaporating as expected. These combined methods will help you determine when your soap has reached its ideal cure state and is ready for use.

Equipment and Tools for Temperature Monitoring

Precise temperature control requires several essential tools for successful soap curing.

You'll need reliable monitoring equipment to maintain ideal conditions throughout the process. An infrared thermometer lets you quickly check soap temperatures, while a digital probe thermometer helps you track both oil and lye measurements in the 120-130°F range.

For thorough temperature management, consider these key tools:

- Temperature and humidity logger to monitor your curing environment

- Heat mat or warming blanket to maintain consistent temperatures in cool spaces

- Soap calculator with temperature guidance for recipe formulation

When you combine these tools effectively, you'll create an ideal curing environment that speeds up the process while ensuring quality results.

Remember that accurate temperature monitoring is vital for achieving properly cured soap bars in the shortest possible time.

Frequently Asked Questions

What Is the Best Temperature for Curing Soap?

You'll get the best soap curing results between 70-75°F (21-24°C). This range guarantees ideal drying and hardening of your bars, while maintaining consistent conditions in a well-ventilated space with humidity below 40%.

Can You Speed up Soap Curing?

You can speed up soap curing by maintaining temperatures between 70-75°F, using fans for better airflow, implementing water discounts in recipes, and trying CPOP methods. These techniques promote faster moisture evaporation and curing.

How to Make Soap Harden Faster?

You'll achieve faster soap hardening by maintaining 120-130°F temperatures, using fans for ventilation, reducing water content, trying CPOP method, and adding rock salt to your mixture during the soap-making process.

What Is the Best Temperature for Saponification?

You'll achieve ideal saponification when you maintain both your oils and lye solution between 120-130°F. Keep them within 10 degrees of each other to guarantee proper chemical reactions and smooth blending during soap making.

In Summary

You'll find that maintaining temperatures between 65-80°F (18-27°C) helps your soap bars cure fastest, but don't rush the process. Remember that proper air circulation matters just as much as temperature control. Keep monitoring your bars with pH strips and hardness tests, and you'll know when they're ready. While higher temps might speed things up slightly, they can also cause quality issues you'll want to avoid.

Leave a Reply