The five best materials for individual soap molds each offer unique advantages for your soap making needs. Premium silicone provides flexibility and easy release, while high-grade plastic delivers affordable durability. Acrylic and PVC excel in transparency for custom designs, and natural wood offers traditional excellence with sharp edges. HDPE stands out as a professional-grade solution for consistent results. Understanding each material's strengths will help you create the perfect bars every time.

Premium Silicone: The Gold Standard for Individual Molds

When it comes to individual soap molds, premium silicone stands out as the most versatile and reliable option available. You'll find these non-toxic molds incredibly easy to use, as they don't require any additional prep work or lining. The flexible material guarantees your soaps release effortlessly, preserving even the most intricate designs.

Premium silicone's exceptional durability makes it perfect for both cold process and melt and pour soap making. You can count on these molds to maintain their shape and functionality for years, withstanding temperatures from -40°F to 446°F.

Their non-stick surface prevents your creations from getting damaged during unmolding, while the variety of unique shapes available lets you craft visually stunning soaps. If you're looking for a long-term investment in your soap making journey, premium silicone individual molds are your best choice.

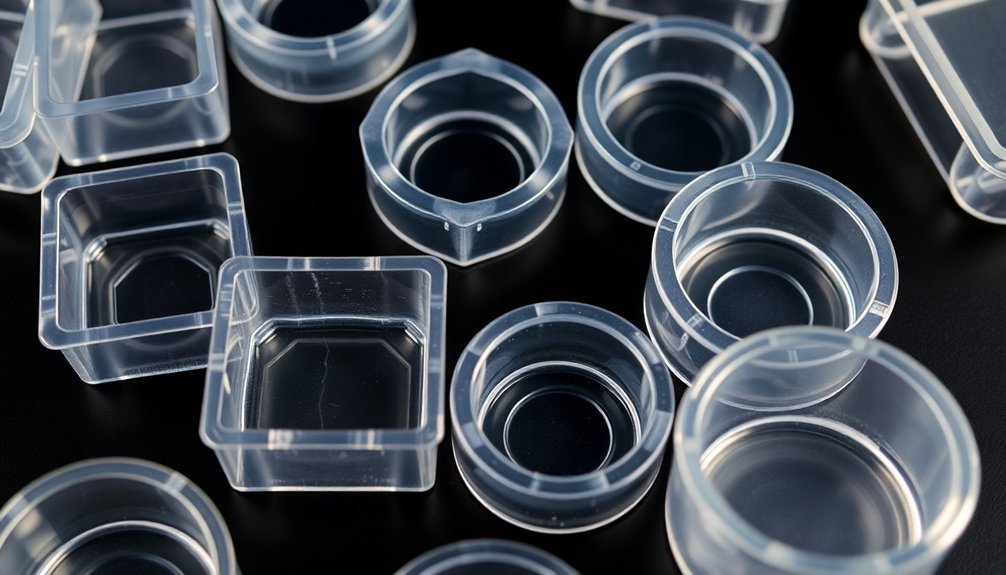

High-Grade Plastic: Affordable Durability for Single Cavities

High-grade plastic molds offer a sweet spot between cost-effectiveness and reliability for soap makers.

You'll find these individual cavity molds, made from polypropylene or polyethylene, provide affordable durability while remaining lightweight and easy to handle. Their non-stick properties guarantee easier unmolding, protecting your intricate soap designs during removal.

When you're focused on soap making, you'll appreciate how these molds deliver precise control over bar sizes and weights, helping you create uniform products consistently.

Unlike cheaper alternatives, high-grade plastic resists warping and cracking, maintaining quality through repeated use. You won't need to worry about scents or colors transferring between batches, as these molds don't absorb soap components.

For artisans seeking professional-grade results without breaking the bank, high-grade plastic molds deliver impressive performance.

Acrylic and PVC: Clear Options for Custom Shapes

Transparency sets acrylic and PVC molds apart in the soap making world, letting you monitor your creations throughout the pouring process. You'll find acrylic molds particularly useful for unique soap designs, while PVC molds offer clear options at a more budget-friendly price point. Both need to be treated properly with mold release agents for easy removal of your finished soaps.

| Feature | Acrylic vs PVC |

|---|---|

| Cost | PVC more affordable |

| Clarity | Acrylic superior |

| Durability | Both prone to cracking |

| Customization | Acrylic custom made |

| Usage | PVC for basic, Acrylic for complex |

When choosing between these materials, consider that acrylic molds excel at intricate patterns and layered designs, while PVC molds work best for simple, puck-shaped soaps. You'll need to handle both types carefully to prevent damage during unmolding.

Natural Wood: Traditional Single-Bar Excellence

Craftsmanship shines through natural wood soap molds, offering you the perfect balance of tradition and precision for single-bar production. You'll achieve professional-looking single bars with sharp edges and clean lines using these durable wooden molds.

Natural wood soap molds blend artisanal tradition with modern precision, delivering professional results through expert craftsmanship and lasting durability.

While they typically require lining with freezer paper to prevent sticking, natural wood provides excellent insulation for cold process soap, enhancing saponification and overall quality.

- Customize your batch sizes by building or purchasing wooden molds that match your specific production needs

- Experience superior insulation properties that promote faster curing and better-quality soap

- Enjoy long-lasting performance with proper maintenance and protection from moisture

Remember to maintain your wooden molds regularly to prevent damage from soap residue and moisture exposure.

With proper care, they'll serve as reliable tools for creating consistently excellent soap bars.

HDPE (High-Density Polyethylene): Professional-Grade Solutions

When durability meets efficiency in soap making, HDPE molds stand out as the professional's choice for consistent, high-volume production.

You'll find these professional-grade solutions excel in impact resistance and maintain their shape through countless uses, making them a reliable investment for your soap-making process.

What makes HDPE molds particularly appealing is their versatility in both loaf designs and slab molds, allowing you to create various soap sizes and shapes.

You won't need to line these molds for most soap recipes, which streamlines your production workflow.

They're incredibly easy to clean, and you won't have to worry about lingering scents or residues affecting your next batch.

If you're serious about soap production, you'll appreciate how these durable molds resist warping and cracking, ensuring consistent results every time.

Frequently Asked Questions

What Is the Best Material for Soap Molds?

You'll find silicone is your best choice for soap molds since it's flexible, durable, and releases soap easily. It won't warp like plastic, doesn't need lining like wood, and unmolds better than acrylic.

Are Silicone Molds Good for Soap Making?

Yes, you'll find silicone molds excellent for soap making. They're flexible, durable, and release soap easily. You can reuse them countless times, they're easy to clean, and they'll help achieve better soap gelling.

Can I Use Parchment Paper for Soap Mold?

Yes, you can use parchment paper in your soap molds. It's an excellent choice that won't stick to your soap. Just make sure you line the mold completely and secure it well before pouring.

What Is the Best Wood for Soap Molds?

You'll find non-treated pine is your best choice for soap molds due to its affordability and insulation properties. If you want more durability, hardwoods like maple and birch work well but cost more.

In Summary

Whether you're new to soap making or an experienced artisan, choosing the right individual mold material makes all the difference. You'll find silicone offers unmatched flexibility, while plastic provides budget-friendly reliability. Clear acrylic lets you monitor your soap's progress, wood adds rustic charm, and HDPE delivers professional results. Pick the material that matches your needs, and you'll create beautiful, perfectly-shaped bars every time.

Leave a Reply