When choosing between wooden and silicone soap molds, you'll need to weigh several key factors. Wooden molds offer superior insulation, durability, and sharp edges, making them ideal for large-scale production despite higher upfront costs. Silicone molds provide flexibility for intricate designs, easy unmolding, and budget-friendly options perfect for beginners. Your choice should align with your production scale, design needs, and long-term goals. Each type has unique advantages that can transform your soap making journey.

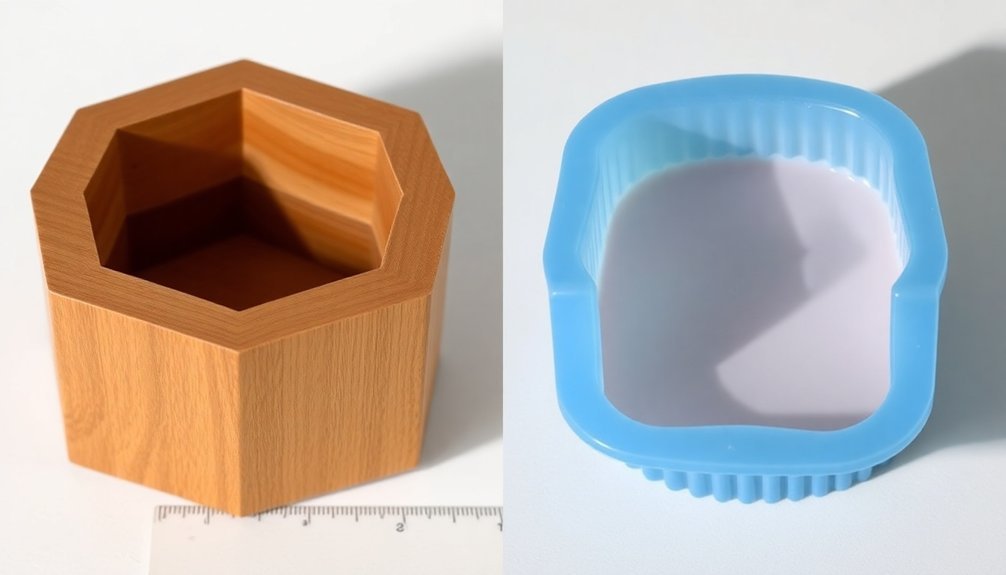

Key Features of Wooden and Silicone Molds

The choice between wooden and silicone soap molds comes down to distinct characteristics that serve different soapmaking needs.

Wooden molds offer superior insulation properties that help your soap gel faster, making them ideal for large batches. While they'll require a release agent or paper liner, they'll maintain their shape indefinitely with proper care.

You'll find silicone molds are remarkably easy to use, especially if you're new to soap making. They don't need any release agent, and their flexible nature lets you pop out finished soaps effortlessly.

These lightweight molds are also dishwasher safe, simplifying cleanup. However, they may stretch over time, which can affect your soap's final shape.

Many soap makers choose wooden molds for durability and consistent performance, while others prefer silicone for its convenience and low maintenance.

Cost and Investment Considerations

While you'll face a higher upfront cost with wooden molds, their durability and professional results can make them a smart long-term investment for serious soap makers.

If you're just starting out, the CraftZee soap making kit with silicone molds at $37.95 offers a more budget-friendly entry point into the craft.

You can always upgrade to wooden molds with silicone liners as your skills progress, combining the best of both options for maximum value.

Initial Purchase Comparison

Making your first soap mold purchase requires careful consideration of both immediate costs and long-term value. When comparing wooden and silicone molds, you'll find distinct differences in initial investment and durability that can impact your soap making journey.

- Wooden molds demand a higher initial investment but offer indefinite longevity with proper care, making them ideal if you're planning large-scale production.

- Silicone molds, like those in the CraftZee kit at $37.95, provide a cost-effective entry point for beginners without requiring additional lining materials.

- While silicone options may stretch over time and affect soap shape, their lower upfront cost makes them practical for testing different designs before committing to wooden molds.

Consider your production volume and long-term goals when choosing between these options, as each offers unique benefits for different stages of your soap making journey.

Long-Term Value Analysis

When evaluating the long-term value of soap molds, you'll need to contemplate both immediate expenses and potential returns on your investment.

While silicone molds appear more cost-effective initially, they mightn't deliver the best value over time.

Wooden molds prove to be a superior long-term asset for several reasons. They'll maintain their shape indefinitely with proper care, unlike silicone molds that can stretch and deform.

You'll also benefit from larger batch production capabilities, reducing your per-bar costs considerably. The enhanced insulation wooden molds provide during the gel phase results in higher quality soap, which can command better prices from your customers.

Though you'll spend more upfront, wooden molds' durability and consistency make them a wise investment if you're serious about soap making.

Budget-Friendly Alternatives

Smart budgeting can help you navigate the initial costs of soap making equipment. When you're starting out, silicone soap molds offer a cost-effective entry point since they don't require additional materials.

While wooden loaf molds represent a long-term investment, they'll need liners that add to your initial investment.

Consider these budget-friendly approaches:

- Begin with silicone molds to minimize upfront costs and simplify your learning process

- If you choose a wooden loaf mold, use freezer paper as an economical liner option

- Start small and upgrade your equipment as your skills and production needs grow

This strategy allows you to test your interest in soap making without a significant financial commitment while leaving room for future expansion into more professional equipment.

Maintenance and Longevity Factors

Although both wooden and silicone soap molds serve similar purposes, they differ considerably in their maintenance requirements and longevity factors.

Wood molds need regular oiling and proper cleaning to prevent soap residue buildup, while silicone molds only require a simple rinse after use.

You'll find that wood molds demand more attention, as you'll need to use liners like freezer paper to protect them from lye and moisture damage.

In contrast, silicone molds don't require special treatment and can last for years when stored in cool, dry conditions.

Regular inspections are essential for both types – check wooden molds for soft spots and silicone ones for stretching or damage.

Your cleaning methods also impact durability; avoid harsh scrubbing on silicone molds, and always use paper liners with wooden ones for easier cleanup and extended life.

Temperature Control and Insulation Properties

When choosing between wooden and silicone molds, you'll discover significant differences in how they manage heat during the soap-making process.

You can rely on wooden molds' natural insulation properties to maintain ideal temperatures for the gel phase without additional measures, whereas silicone molds often require extra insulation like towel wrapping.

Your choice between these materials will directly impact temperature control, as wooden molds provide consistent heat distribution for even saponification, while silicone molds might need sodium lactate to compensate for their slower gelling process.

Heat Management Differences

Since temperature control plays an essential role in soap making, understanding the heat management differences between wooden and silicone molds can significantly impact your final product.

Wood's superior insulation properties will help you maintain consistent temperatures throughout the curing process, promoting even gelling and smoother textures in your soaps.

When working with these different materials, you'll want to take into account:

- Wood naturally retains heat better, making it easier to achieve proper gelling without additional steps.

- Silicone molds require extra temperature regulation, often needing oven processing at 110°F for best results.

- You'll need to compensate for silicone's lower insulation by using external heat management techniques, such as wrapping molds in towels.

Your choice between wood and silicone will directly affect your temperature control strategy and ultimately influence your soap's final consistency.

Insulation Performance Comparison

Understanding insulation performance between wooden and silicone molds is essential for achieving consistent soap quality.

Wooden molds offer superior insulation properties that greatly improve your soap's heat retention during the critical gel phase. You'll find that wood's natural insulating qualities help maintain consistent temperatures, resulting in better color consistency and smoother surfaces.

When you're using silicone molds, you'll face challenges with heat retention, which can lead to uneven gelling and potential issues like soda ash or patchy coloring.

While you can compensate by placing silicone molds in a warmed oven, wooden molds naturally provide the best environment for temperature control. The efficient insulation of wooden molds means you'll need less external heat to achieve the desired gel phase, ultimately producing soap with fewer defects and more uniform characteristics.

Shape Retention and Design Possibilities

Although both wooden and silicone soap molds offer distinct advantages for crafting, they differ considerably in their shape retention and design capabilities. When comparing wood vs silicone molds, you'll find each excels in specific areas.

- Wooden molds deliver consistently sharp edges and defined shapes, making them perfect for professional-looking bars that maintain their form over time.

- Silicone molds shine in flexibility, allowing you to create intricate designs and easily remove complex shapes, though they may stretch slightly with repeated use.

- Custom molds are possible with both materials – wooden molds through traditional construction methods for larger batches, while silicone mold-making techniques enable unique decorative patterns for smaller runs.

You'll need to take into account your production scale and design goals when choosing between these options, as each offers unique shape retention and design possibilities.

Practical Usage Tips and Best Practices

To achieve the best results with both wooden and silicone soap molds, you'll need to follow specific handling practices for each material.

Different mold materials require different handling techniques – mastering these practices ensures your soap-making success with both wood and silicone.

When using wooden molds, line them with freezer paper to prevent sticking and make cleanup easier. Silicone molds don't require lining, but you'll want to monitor their condition as they can stretch with repeated use.

For successful unmolding, give your soap adequate setting time – about 24 hours for wooden molds, while silicone molds might need longer.

If you're working with silicone molds, add sodium lactate to your soap mixture to prevent overheating and accelerate hardening.

After use, clean your molds thoroughly. While silicone molds are easy to rinse, wooden molds need extra attention to avoid soap residue buildup on their exterior surfaces.

Frequently Asked Questions

Can You Use Silicone Cake Molds for Soap Making?

Yes, you can use silicone cake molds for soap making! They're perfect for beginners since they're flexible, non-stick, and don't need liners. Just make sure you're using food-grade silicone for safe soap production.

Which Mould Is Best for Soap Making?

You'll find both wooden and silicone molds have their merits. If you're a beginner, start with silicone for its flexibility and easy cleanup. For larger batches and professional production, wooden molds are ideal.

Can You Put Cold Process Soap in Silicone Molds?

Yes, you can safely use silicone molds for cold process soap. They're ideal for easy unmolding and won't warp from saponification heat. Consider adding sodium lactate to help your soap harden faster in these molds.

What Is the Best Wood for Soap Molds?

You'll find untreated pine is your best choice for soap molds. It's affordable, durable, and provides great insulation. Cedar and poplar are good alternatives, but remember to line any wood mold with freezer paper.

In Summary

Both wooden and silicone molds offer unique advantages for your soap making journey. You'll find wooden molds excel in insulation and longevity, while silicone provides flexibility and intricate design options. Consider starting with silicone for simple projects, then invest in wooden molds as you advance. Whatever you choose, proper maintenance and understanding temperature control will help you create beautiful, professional-quality soaps.

Leave a Reply