You'll need a lye calculator to guarantee your handmade soap is both safe and successful. Since each oil requires a specific amount of lye for proper saponification, guessing these measurements can lead to harsh or ineffective soap. A calculator precisely determines the correct lye-to-oil ratios, preventing costly mistakes and potential skin irritation. Understanding these critical measurements helps you customize superfat levels and create the perfect bar for different skin types. The science behind these calculations reveals fascinating insights about soap crafting.

The Critical Role of Precise Lye Measurements

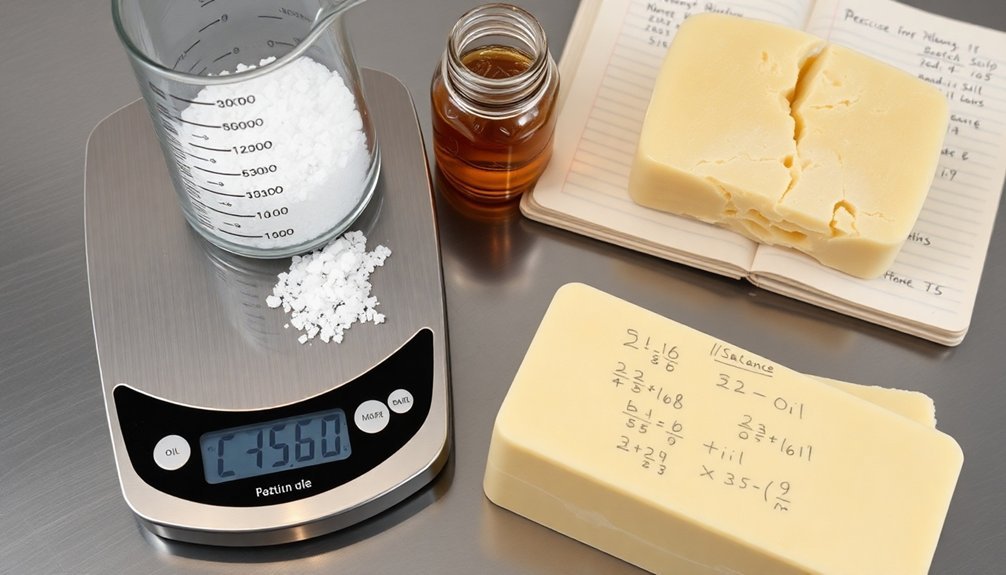

When making soap, precise lye measurements stand as the cornerstone of successful and safe production.

You'll find that using a lye calculator eliminates guesswork and guarantees your soap isn't too harsh or too mild. By providing exact measurements for your specific oil combinations, these calculators help you maintain consistency in your soap quality and characteristics.

The saponification value formula enables accurate calculation of the required lye amount for each oil type.

You can avoid costly mistakes and safety hazards by letting the calculator determine the perfect lye-to-oil ratio.

Whether you're creating a new recipe or replicating an existing one, you'll achieve reliable results every time. This precision greatly reduces the trial-and-error approach that often leads to wasted materials and inconsistent batches.

With accurate calculations, you're not just saving time and resources – you're guaranteeing that each batch meets your quality standards.

Understanding Saponification Values and Oil Properties

To create safe and effective soap, you'll need to understand saponification values (SAP values) and how different oils behave in your recipes.

Digital scales ensure exact measurements needed for proper saponification ratios. These values tell you exactly how much lye is needed to transform oils into soap. When using sodium hydroxide (NaOH) for bar soap, you'll need to convert the SAP values from potassium hydroxide (KOH) by dividing by 1.403.

Different oils contribute unique properties to your final product:

- Coconut oil creates abundant, fluffy lather but can be drying

- Olive oil provides gentle moisturizing properties with minimal lather

- Palm oil adds hardness and stability to your bars

- Cocoa butter contributes to a creamy, stable lather

- Avocado oil offers superior moisturizing for sensitive skin

Understanding these characteristics helps you balance your recipe for the perfect combination of cleansing, lathering, and moisturizing properties.

Safety First: Preventing Common Lye Calculation Errors

Safety in soap making relies heavily on precise lye calculations, since even small errors can result in harsh or dangerous products.

You'll need to maintain a lye solution strength between 25% and 28%, ensuring you don't use too little water, which can lead to uneven saponification and unsafe soap.

Always use a lye calculator when adjusting your recipe, as each oil requires different amounts of lye for proper saponification.

Don't swap oils without recalculating, as this can create excess lye or unsaponified oils in your final product.

Keep your water-to-lye ratio between 1:1 and 3:1, with 1.5 or 2 times the lye weight being ideal. Alternative liquids like goat's milk can be incorporated while maintaining proper lye solution ratios.

Streamlining Complex Recipe Formulations

Modern lye calculators have revolutionized the complex process of formulating soap recipes by eliminating tedious manual calculations and potential errors. You'll find these tools invaluable when working with multiple oils and fats, as they automatically determine precise lye amounts and predict your soap's properties. Beginners especially benefit from using tried and tested recipes through these calculators to ensure safety and effectiveness.

Whether you're making bar soaps with NaOH or liquid soaps with KOH, these calculators help you customize recipes while maintaining proper chemical balance.

- Input your chosen oils and amounts to get exact lye measurements

- Preview soap qualities like hardness, conditioning, and lather

- Adjust ingredient percentages to achieve desired characteristics

- Mix multiple oils while maintaining proper saponification values

- Switch between different soap types with automatic adjustments for NaOH or KOH

These features guarantee you'll create consistent, well-balanced soap formulations while saving time and reducing mistakes.

Customizing Superfat Levels for Different Soap Types

You'll need to adjust your soap's superfat levels based on your target skin type and desired moisture content.

Whether you're making a gentle facial bar requiring higher superfatting or a basic body soap with moderate moisturizing properties, your lye calculator helps determine the precise oil-to-lye ratios.

Each oil recipe requires calculating the specific SAP value to achieve proper saponification of the ingredients.

Your choice of superfat percentage directly impacts how moisturizing and gentle your final product will be on the skin.

Adjusting Moisture Content Ratios

While standard soap recipes often call for fixed moisture ratios, customizing your water-to-lye ratio and superfat levels allows you to create soaps tailored for specific purposes.

You'll need to balance between cure time, soap hardness, and workability when adjusting your moisture content. A 25% lye solution gives you more working time but requires longer curing, while a 40% solution speeds up curing but demands quicker handling.

- Use a 2:1 water-to-lye ratio if you're new to soap making

- Choose 33% lye solution for balanced curing and workability

- Keep water amounts at least equal to lye weight for proper dissolution

- Reduce water content for harder bars and faster curing

- Avoid exceeding 3:1 water-to-lye ratio to prevent soap volcanoes and separation

Targeting Skin-Type Benefits

Beyond adjusting moisture content, superfatting your soap recipe allows you to create products tailored for specific skin types and conditions. You'll need to carefully balance the superfat percentage to achieve ideal results for your target users while maintaining proper lather and bar hardness.

| Skin Type/Need | Recommended Superfat % |

|---|---|

| Normal Skin | 3-5% |

| Dry/Sensitive | 6-8% |

| Oily/Acne-Prone | 1-3% |

| Mature Skin | 5-7% |

| Body Bars | 4-6% |

When formulating your recipe, start with a minimum 1-3% superfat to guarantee all lye is consumed. You can then increase this percentage based on your target skin type. Remember that higher superfat levels will create milder soap but may reduce lather quality and bar longevity. Test different percentages to find the sweet spot for your specific oil blend.

Balancing Water-to-Lye Ratios Effectively

Mastering the water-to-lye ratio stands as a critical foundation for successful soap making.

You'll need to understand that the minimum water required equals the weight of your lye, ensuring complete crystal dissolution. For beginners, a 33% lye concentration provides ideal working time, while experienced crafters often use 37-40% concentrations for faster results.

- Higher concentrations speed up the gel phase but require careful handling

- Water discounting affects your soap's properties and workability

- Your superfat percentage influences the final water-to-lye ratio

- Fresh ingredients may require ratio adjustments to maintain consistency

- Never exceed a 1:2.1 lye-to-water ratio for safety

Predicting Final Soap Characteristics

Understanding your soap's final characteristics before you make it helps guarantee successful batches and consistent results. A lye calculator analyzes your recipe and predicts key properties, including cleansing power, conditioning effects, and lather quality.

| Property | What It Measures | Why It Matters |

|---|---|---|

| Hardness | Bar firmness | Determines shelf life and durability |

| Cleansing | Dirt removal | Affects skin cleaning effectiveness |

| Conditioning | Moisturizing | Impacts skin feel after use |

| Lather | Bubble formation | Shows washing experience |

| Longevity | Soap stability | Indicates value and storage life |

You'll also see how superfatting affects your final product, with precise calculations ensuring you don't end up with lye-heavy or overly oily soap. The calculator accounts for each oil's unique properties, helping you blend ingredients effectively to achieve your desired soap characteristics.

Recipe Development and Oil Substitutions

When you're modifying soap recipes, using a lye calculator guarantees your adjustments remain safe and effective, especially as different oils require specific lye amounts for proper saponification.

You'll find that even small changes in oil ratios can greatly impact your soap's final properties, from hardness to lather quality.

Your lye calculator will help you maintain the correct balance of ingredients while experimenting with various oil combinations, protecting both the success of your recipe and the safety of your final product.

Safe Recipe Modifications

Safe recipe modifications represent a critical aspect of soap making that requires careful attention to lye calculations and oil properties.

When you're modifying recipes, you'll need to use a lye calculator to guarantee your soap remains safe and effective. Different oils have unique saponification values, so swapping ingredients isn't as simple as a one-to-one substitution.

Key considerations for safe modifications:

- Always recalculate lye amounts when substituting oils

- Choose replacement oils with similar properties to maintain desired characteristics

- Keep temperature differences between lye solution and oils within 10°F

- Consider the impact on hardness, lather, and moisturizing qualities

- Use protective equipment and follow safety guidelines

You can adjust your recipe for specific qualities by incorporating additives like sodium lactate for hardness or castor oil for increased lather, but remember to verify all changes through your lye calculator.

Oil Ratios and Properties

The complex interplay between different oils forms the foundation of successful soap making, with each oil contributing distinct properties to your final product.

You'll need to balance hard oils like coconut and palm oil, which create long-lasting bars with rich lather, against softer oils like olive oil that provide gentle conditioning.

Base oils determine your soap's primary characteristics, while specialty oils enhance specific qualities.

A lye calculator helps you maintain proper ratios when substituting oils. For example, if you're replacing palm oil with coconut oil, you'll need to adjust your lye amount since these oils require different saponification values.

Understanding oil properties lets you create bars with your desired hardness, lather, and skin benefits.

Remember that using a single oil type won't give you ideal results – it's the combination that creates well-balanced soap.

Managing Batch Sizes and Scaling Recipes

Managing batch sizes effectively can transform your soap making from a time-consuming hobby into an efficient production process.

You'll save significant time by masterbatching your oils and lye for multiple days, while scaling up your batches dramatically increases output with minimal extra effort. A 125-pound batch, for example, takes just five minutes longer than a five-pound batch.

- Use large slab molds instead of multiple small ones to reduce prep and cleanup time

- Masterbatch both oil and lye mixtures for an entire week's production

- Scale up your recipes to maximize efficiency and minimize labor costs

- Implement a two-step cutting process for large blocks: loaf cuts followed by bar cuts

- Consider using an Air Cutter mold system for producing hundreds of bars with fewer cuts

When scaling recipes, your lye calculator becomes essential for maintaining precise measurements and ensuring consistent quality across larger batches.

Advanced Properties and Soap Quality Control

You'll gain essential insights into soap quality through systematic testing methods that measure pH levels, hardness, and lather characteristics.

Your soap's properties can be accurately predicted using specialized lye calculators that analyze the specific qualities of different oils and their ratios.

Testing and prediction tools work together to help you maintain consistent quality across batches while ensuring your soap meets safety standards and desired characteristics.

Quality Testing Methods

Professional soap makers rely on rigorous quality testing methods to verify their products meet industry standards and consumer expectations.

You'll need to understand and perform various tests to ascertain your soap's quality and consistency. These tests measure chemical composition, physical properties, and performance characteristics.

- The acid value test helps you monitor free fatty acids that affect shelf life.

- Total Fatty Matter (TFM) testing determines your soap's cleansing effectiveness.

- pH testing verifies your soap is skin-safe and performs effectively.

- Moisture content testing prevents mold growth and maintains proper hardness.

- Foam stability testing confirms your soap creates lasting, rich lather.

Soap Property Predictions

Successfully predicting soap properties requires understanding how different ingredients interact and affect the final product.

You'll need to take into account multiple factors including hardness, longevity, conditioning, and lather quality when formulating your recipe.

The INS score helps you gauge your soap's overall quality, with an ideal value of 160.

You'll want to monitor the iodine value, as lower numbers create harder but less conditioning soap, while higher values yield softer, more moisturizing bars.

Water content greatly impacts your soap's hardness and curing time.

Lye calculators like Soapcalc and SBM Crafters make these predictions easier by analyzing your oil combinations and lye amounts.

You can adjust water discounting, superfat levels, and lye concentrations to achieve your desired soap properties while maintaining safety and quality.

Frequently Asked Questions

Can I Use a Lye Calculator for Making Liquid Soap?

Yes, you can use a lye calculator for liquid soap. You'll need to select potassium hydroxide (KOH) instead of sodium hydroxide (NaOH), and guarantee you're using a 10% lye concentration for proper liquid consistency.

How Long Does Lye Solution Need to Cool Before Use?

You'll need to let your lye solution cool for 1-3 hours until it reaches 120-130°F. You can speed up cooling with a cold water bath, but don't rush it – proper temperature is essential.

What Happens if I Accidentally Use Expired Lye?

If you use expired lye, your soap won't saponify properly and may remain soft or sticky. You'll likely end up with unsafe soap containing lye pockets. It's best to discard the batch and start fresh.

Should I Adjust Calculations When Using Goat Milk Instead of Water?

Yes, you'll need to adjust your calculations when using goat milk instead of water. The milk's natural fats affect saponification rates, so use a lye calculator that specifically includes goat milk as a liquid option.

Can Temperature Differences Affect Lye Calculator Measurements?

No, temperature won't affect your lye calculator measurements. While temperature impacts soap-making reactions and mixing processes, the calculator's chemical calculations remain constant regardless of temperature. You'll still use the same amounts specified.

In Summary

Using a lye calculator isn't optional – it's essential for your soapmaking success and safety. You'll avoid dangerous miscalculations, create consistent batches, and understand how different oils affect your final product. Whether you're scaling recipes, adjusting superfat levels, or experimenting with new formulations, this tool helps you craft safe, high-quality soaps while taking the guesswork out of the saponification process.

Leave a Reply